In this blog we had the pleasure to interview Prof. dr. ir. Krijn P. de Jong (emeritus), a leading expert in heterogeneous catalysis. Prof. De Jong shared his expertise on the application of in situ transmission electron microscopy (TEM) which allows researchers to observe catalytic processes in real-time at the atomic level, providing a deeper understanding of how catalysts operate. By correlating these observations with bulk-scale experiments, scientists can gain comprehensive insights into the mechanisms driving catalytic reactions, supporting innovation of catalytic materials. Prof. De Jong’s discussion highlights the potential of in situ microscopy in bridging the gap between nanoscale and bulk-scale experiments, ultimately advancing the efficiency and effectiveness of catalytic systems.

Thank you for joining this interview! Can you tell us a little more about your background and the field that you are active in?

I worked in the field of catalysis throughout my entire career, which started in industry where I worked at Shell for 15 years, followed up with 24 years as a full professor at the group of Inorganic Chemistry and Catalysis at Utrecht University. Although I have been professor emeritus for a couple of years, I still remain active in the field. For instance, I am connected with Utrecht University, advisory roles for institutes and scientists, and I frequently visit various countries, such as China, where I teach students about heterogeneous catalysis related to sustainability.

University Utrecht David de Wied building, location of the inorganic chemistry and catalysis group.

Are there any topics within heterogeneous catalysis that you have been more passionate about compared to others?

There have definitely been two areas of focus for me over the years. First, I have always been interested in the preparation of catalyst materials. This means we can look at the catalyst structure and composition at the nanoscale to finally improve or understand the catalyst behavior. Second, I have devoted a large part of my career to C1-chemistry. With this chemistry we can convert synthesis gas (H2/CO), which can be obtained from renewable resources such as municipal waste, biomass or CO2, into chemicals and fuels.

You have a background in catalysis, from both academic and industry settings. From your experience in both sectors, what motivated you to add in situ microscopy to your list of analysis techniques that were already in house?

This all started off with a need to answer scientific questions and broadening our techniques. Our questions were centered around how nanoscale effects play a role in local effects and in global effects. These global effects say something about how our catalyst behaves on the whole, meaning metallic nanoparticles together, while the local effects say more about how the catalyst behaves at the level of individual particles. In other words, we wanted to not only focus on the forest, but also be able to observe trees. However, research is dependent on funding, thus we worked hard to obtain an ERC advanced grant in 2013. This grant allowed us to start studying the ‘genesis of supported metal catalysts’, in which we could find answers to improve catalyst preparation and investigate both local and global effects.

Why did you choose (commercial) gas cell studies over, for instance, other well-known techniques such as environmental TEM (ETEM)?

In an ETEM we need to modify a microscope to be able to introduce gasses, still at low pressures, so that we are able to observe nanoscale reactions. Unfortunately, this is not easily comparable with the bulk experiments since the ETEM couldn’t handle high enough pressures,. With an in situ cell, there is no need to modify the microscope and you can just plug in the cell to start to work on these topics immediately. Additionally, all the micro-electromechanical systems (MEMS) that are used with in situ gas cell systems can add heating and work at 1 bar pressure. Compared to ETEM, this is an enormous step forward for catalysis studies.

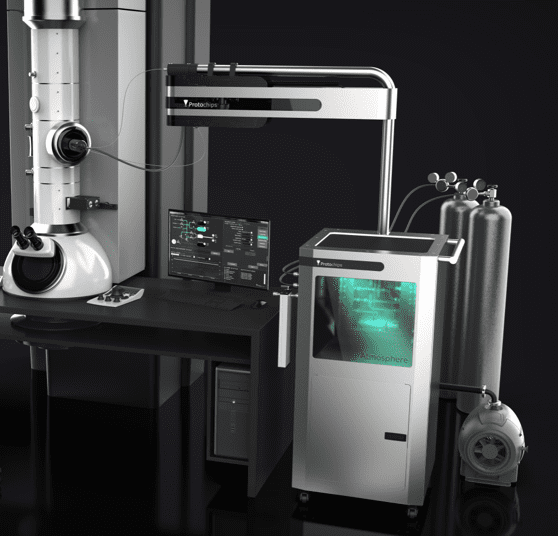

The Atmosphere AX, gas cell in situ, system including residual gas analyser and manifold system.

What kind of challenges do you see that are tied to in situ gas phase electron microscopy?

There are always challenges associated with all types of research, but you can also see this as new opportunities to learn. With in situ microscopy, the challenges are both technical and scientific. When I am talking about technical challenges, I mean that students need to be trained extensively before they can start using the (in situ) systems. In our current culture, students usually approach research with eagerness and drive to publish. This leads to enthusiastic students who might want to try doing complex studies in the system immediately. From my experience I can say that it is important to use a stepwise approach to be successful. An expression that describes this well is “learn to walk before you start to run”. In other words, it is important to understand and master these things step by step, even though it might not be exciting, it is important to understand research results properly.

On top of extensive training, it is important to ask scientific questions that can be answered with such a technique. If we start using an in situ system in our microscope, we might capture beautiful images, however, what does this actually mean and how do we connect this to our bulk studies? Even though it might not be very attractive to start doing screening studies, it is necessary. A previous colleague used to say ‘een plaatje voor een praatje’ (In Dutch translated: ‘a picture for a talk’), meaning that some people will take nice images and to enlighten a scientific talk. This unfortunately still happens with microscopy studies. The field of in situ microscopy might need some more years to mature. This is why I usually recommend a workflow to connect the bulk to nano and therefore make the research more than just a pretty video/image.

Review article on in situ heterogeneous catalysis from Van der Wal, L.I., et al. (2021) Catalysis Science & Technology, 11, 3634–3658

If new users want to be successful with in situ TEM, do you feel it is important for them to be experts in both catalysis and electron microscopy? Or would you think it is better to have two separate experts that collaborate?

Speaking from my experience, our group’s expertise was not in electron microscopy, though, we were lucky to have the Utrecht University EM center close by. This center has a high technical level, including top-notch people that constantly operate the microscopes. Our catalysts experts then worked together with not only the microscopists but also other application scientists from different fields, including geography, life-science and physics, to exchange experiences and get meaningful scientific results.

So for me, the complexity of the research is an important factor here. If there is a complex research question, but the (chemistry) student or supervisor already has a good background in microscopy, it is perfectly fine to combine the two expertises. However, many institutes starting within the field of in situ microscopy have a lot to learn on how the technical equipment works and also what can an cannot be done from the materials science point of view. My advise is to not try to master two complexities at the same time, rather, it might be better to collaborate between students/supervisors from different fields. Therefore, the English saying ‘Jack of all trades but master of none’ is appropriate and my advice is to look for collaboration and working together. This is not only the case for PhD/PostDocs but also for supervisors.

Over the last 10 years, many gas phase electron microscopy studies have focused on fundamental phenomena (e.g. particle reduction and oxidation, but only in the microscope) without correlating these results to bulk scale analyses. More recently, there seems to be a shift in mentality where more researchers are interested in understanding this correlation – what do you think about this mentality shift?

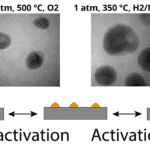

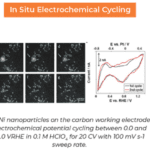

In catalysis, if you only study one particle, how can you couple that to industrial scale relevance? When I review papers nowadays, I usually try and ask whether or not the authors show that the nanoscale results are in some way coupled to the bulk. Researchers can do this by not only showing microscopy results, but combining this in their research papers with bulk scale techniques such as X-ray Diffraction, temperature programmed reduction (TPR) studies or spectroscopy. This means stepping away from the microscope and obtaining experiments that are done at lab scale. If these ex situ and in situ results do not match, there can be a discussion on why this is. It could be due to electron beam effects, ramp rates, differences in temperatures or even partial pressures and hydrodynamic differences. Changing these factors in the in situ cell can then give in indication on what makes the in and ex situ different. An example of ex situ and in situ studies was shown in our recently published work, by Savannah Turner, where we compare TPR results to in situ results and find how different temperatures combined with the addition of water vapor can have large effects on particle formation in nickel catalysts. Only an in situ study combined with bulk scale could provide such new insights into the growth of metal nanoparticles.

Work from Turner, Savannah.J. et al. (2024) Small, 2401009.

What capabilities would you like to see added to gas phase EM to help with the comparison to bulk scale? Is there any type of research that you are specifically looking forward to seeing?

Technology wise, I understand that people within the field of microscopy always would like to see higher resolution images. Developing better detectors in microscopes, working on the sample thickness and even window thickness are important factors that needs focus. Graphene windows would be a nice addition, however, I do understand that this is challenging to fabricate commercially.

Additionally, I would love to see more studies that compare actual bulk scale studies to the nanoscale. However, there are more gaps that need to be filled such as the pressure gap between in and ex situ catalysis studies. Most systems can only go to 1 bar, while operational catalysts function at >20 bar. Lastly, something that has not been talked about much, but is in my opinion is of importance is the hydrodynamics gap. In an in situ system, the flow pattern of the gasses through the cells are completely different then a standard continuous stirred tank reactor (CSTR) or plug flow reactor. As far as I know, there is not much known about the actual flow patterns in the in situ cells. If we want to compare the reactions in and ex situ, we need more information on this topic.

What type of experimentation would you like to see that has not been done yet in in situ microscopy for heterogeneous catalysis research?

I have not seen results from a ‘round-robin test’. In this case one particular experiment will be repeated at different universities, with different microscopes and different operators. Using such an experiment, we would be able to compare if the systems with these samples are indeed reproducible and how we can optimize the in situ workflows.

Thanks to Professor de Jong for sharing his experience in the catalyst field. To learn more about his research, see the following publications.

Watch our video on heterogeneous catalysis for in situ microscopy here!