Did you know that you can observe the performance of resistive random-access memory (RRAM) devices in real time at the nanoscale? Understanding the performance of RRAM devices is integral to improve their reliability and functionality. As an example, it is possible to create multiple microstructures, test them individually and then observe their endurance and performance using transmission electron microscopy (TEM). Pretty cool, right?

With the Fusion AX system from Protochips, you can bias nanoscale devices while observing fundamental changes to these devices in real time. Here is a sneak peak of how this is possible:

- Preparation: Sample preparation and deposition are critical but tedious steps in all in-situ TEM experimental workflows. Electronic devices are usually created using focused ion beam preparation, for which Protochips has designed a FIB stub tool and specialized E-chips. This leads to successful, consistent and easy preparation, where thinning of the lamella can be done after attaching to the E-chip.

- Collection: Once Fusion AX is fully set up and TEM-ready, electrical biasing can be done with the same software as the data collection. Biasing of small devices can trigger movement, therefore Fusion AX comes equipped with machine vision software, AXON Synchronicity, providing live physical and digital correction as well as metadata indexing and integration.

- Analysis: With Fusion AX’s friction-free tilting in two directions, EELS and EDS data can be collected during and after biasing experiments. With these methods, not only can you observe structural changes, but the chemical changes of electronic devices simultaneously.

- Publishing: Once all the data has been collected and analyzed, data processing can begin. With AXON Studio, researchers can easily filter, plot, sort, create videos and images and visualize trends after an experiment is completed. Since all metadata is integrated into a single software, data correlation and analysis are tremendously accelerated and easily shared.

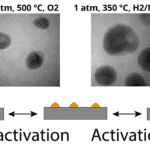

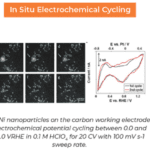

In this example, the oxidation states of pristine and cycled devices were observed using EELS spectroscopy on Pt/NiO/Nb2O5 x/Pt bilayer RRAM devices. This study offers valuable insights into the optimal structural design for enhanced electrical performance and reveals the switching mechanism of the Pt/NiO/Nb₂O₅ₓ/Pt bilayer RRAM device, paving the way for advancements in multilayer devices for memory applications.

Wang, C.-H. et al. (2024) ‘Enhanced resistive switching performance and structural evolution of NiO/Nb2O5−x bilayer memristive device’, Journal of Alloys and Compounds, 983, p. 173889. Available at: https://doi.org/10.1016/j.jallcom.2024.173889.

With this workflow, scaling bulk electronic device experiments to the nanoscale becomes easier, while maintaining the highest level of scientific rigor to publish relevant, reproducible and reliable results.

Want to know more about electronic device research using in situ microscopy? Look up our one pager here!