Fusion AX Components

The Fusion AX in situ heating and biasing system is designed to give you the freedom to experiment with different biases, temperatures and with a large variety of nanoscale samples. Every Protochips in situ system is driven by the AXON machine-vision software, using a wide variety of MEMS-based E-chips and accessories to best fit your research needs. All of these components are fully approved by the major microscope manufacturers to meet their rigorous standards for safety, compatibility, and reliability.

See More

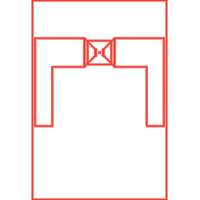

Fusion AX System

SAMPLE PREPARATION

Tools

→ Shadow mask, FIB stub, and inspection holder for quick, reproducible sample prep from user to user

COLLECTION

Machine-Vision Software: AXON

→ Automated drift and focus correction

→ Real-time electron dose monitoring even as samples move in and out of field of view

→ Full indexing of TEM, camera, and in situ metadata for filtering and plotting of parameters

→ Free offline analysis software for streamlined all-in-one data visualization

ANALYZE

Heating, biasing and electrothermal holder

→ Low-profile holder walls for fast EDS mapping

→ Friction-free double tilt design for stable delivery of heating and electrical stimuli even while tilting

→ Modular design enables adding capabilities at a later date without holder downtime

PUBLISH

Analysis Software: AXON Studio

→ Free offline analysis software for streamlined all-in-one data visualization

Sample Preparation

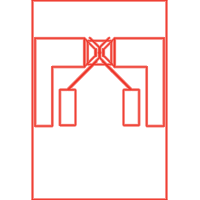

The Fusion AX system uses custom-made microelectromechanical systems (MEMS) as sample supports to create the in situ conditions within the TEM. All E-chips are designed, fabricated, and quality checked in-house, which gives Protochips an immense amount of control and oversight to ensure quality, proper functionality, and keep cost minimized.

Fusion AX heating E-chips uses a patented silicon carbide heating membrane instead of a traditional metal coil that has superior uniformity and offers multiple support membranes, such as thin holey carbon and amorphous silicon nitride, to enable you to choose the best material to maximize imaging resolution. The heating membrane can reach 1200 °C and each E-chip comes individually calibrated with its own calibration file to ensure any wafer-wide variations from manufacturing are taken into account.

Fusion AX electrical E-chips are designed with a unique silicon substrate to mitigate electrical leakage and parasitics, enabling accurate electrical characterization of nanoscale samples. Multiple configurations of electrical E-chips are offered to provide flexibility for sample shape, size, material, and desired electrical conditions. FIB-optimized E-chips are also offered to provide a means of simplified lamella preparation onto the E-chips that is successful every time.

If temperature-dependent electrical characterization is desired, the Fusion AX electrothermal E-chips use the same patented silicon carbide heating membrane, but also contain electrical leads patterned on top the membrane. Patterning the electrical leads on top of the heating membrane ensures the temperature at the sample is accurate, with no offset to consider. Fusion AX electrothermal E-chips can reach temperatures up to 900 °C.

Do you want to know more about our E-chips, click here to visit our E-chips page

Machine-Vision Software: AXON

For in situ applications, AXON Synchronicity and AXON Studio work hand in hand with our Fusion AX system. AXON Synchronicity machine-vision software allows you to focus on on the sample and not the TEM controls, as heating, biasing and other metadata is all integrated. Live image streams fully enriched with TEM, camera/detector and in situ metadata are easily organized, viewed, filtered and published. Discover subtle trends in your data that would have previously gone unnoticed and find your breakthrough.

Click here to learn more about AXON